| The

2003 earthquake in the ancient Iranian city of Bam measured 6.6

on the Richter scale and killed over 40,000 people. Even though

the 1989 Loma Prieta earthquake that hit the San Francisco area

measured 7.1 on the Richter scale, 62 people lost their lives. California's

dramatically lower death toll is in large part due to scientists'

increasing understanding of how buildings react to earthquakes,

and the new technologies they have developed to help structures

withstand them.

The actual

distance that buildings move during an earthquake is not usually

that great compared to their size, and on its own does not cause

much damage. It is the buildings' acceleration -- how quickly

they speed up when the ground begins to shake -- that can cause

them to collapse. That acceleration and the buildings' weight

are the two main factors that determine how much strain an earthquake

exerts on a structure.

A factor that

can exacerbate the damage an earthquake causes is each building's

natural tendency to sway back and forth at a particular rate.

That rate tends to vary depending on a building's height -- with

shorter buildings tending to sway more quickly than taller buildings.

When the ground is shaking at the same rate as a building, its

response to the earthquake is amplified and in some cases it can

begin to accelerate more than twice as quickly as the ground beneath

it.

In the 1985

Mexico City earthquake, over half the buildings that collapsed

were about 20 stories  tall,

because those buildings' natural tendency to sway matched the

ground's movement during the earthquake. tall,

because those buildings' natural tendency to sway matched the

ground's movement during the earthquake.

Another factor

influencing a building's ability to withstand temblors is the

ground under the building. Looser soil shakes more violently than

firmer soil, which itself moves more than hard rock during a quake.

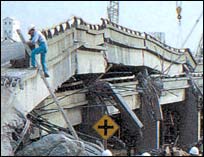

Scientists blamed this phenomenon for the collapse of a stretch

of a double-decker Oakland, Calif., highway during the 1989 earthquake

in San Francisco. According to the U.S. Geological Survey, the

ground under that stretch of the road was man-made fill over soft

mud, and so it shook more than the ground under the rest of the

highway.

Engineering

buildings that can survive earthquakes

The

conventional approach to building earthquake-resistant buildings

was to make them strong enough to withstand the force of the ground's

movement. The engineers working on such buildings configured combinations

of floors, walls, beams and columns knowing each one's ability

to keep the building upright during an earthquake.

Over the past

25 years, more advanced techniques have aimed to make structures

safe during an earthquake by reducing the amount that ground shaking

impacts them.

One method

that scientists are using is placing something underneath the

building that can absorb much of the energy from an earthquake.

Placing layers of rubber and steel between a building and its

foundation is one way to lessen the damage. The buffer is designed

to keep up- down

motion to a minimum, while being able to move side-to-side when

the ground moves. down

motion to a minimum, while being able to move side-to-side when

the ground moves.

In an earthquake,

a building that sits on top of such a device will still sway but

is much less likely to be damaged. According to researchers at

the University of Buffalo, experiments show that these devices

can cut the forces that shake a building during an earthquake

by 25 percent.

The device

also slows down the side-to-side motion of an earthquake on buildings,

bridges and other structures. During an earthquake, structures

with one of these systems will rock back and forth like a boat

on the ocean, but will not break apart, Michael Constantinou,

co-director of the University of Buffalo's earthquake simulation

laboratory, told the Online NewsHour.

Often there

is a lead plug in the middle of the device that gives off heat

as it bends back and forth during an earthquake. By converting

some of the energy from the shaking into heat, it makes the overall

device more effective by preventing some of the energy from being

transferred into the building.

Another system

that works on a similar principle uses a device that slides along

a curved surface that is higher on the edges than it is in the

middle. During an earthquake, the device moves freely along the

curved surface and the upward slope of the sliding surface dampens

the overall motion. Researchers at the Multidisciplinary Center

for Earthquake Engineering Research tested these devices on shaking

tables that mimic earthquake movements and found that they made

a building able to withstand an earthquake six times stronger

than it would have been able to without protection.

This technology

was used in 1994 to make San Francisco's U.S. Court of Appeals

building, which dates back to 1905, safe for possible future earthquakes.

The system was made up of 256  individual

devices that rolled back and forth, according to Constantinou. individual

devices that rolled back and forth, according to Constantinou.

Another strategy

that engineers are using is outfitting buildings with devices

that dissipate energy that would shake a building back and forth

during an earthquake. These dampening devices are typically part

of the bracing connecting floors to one another and assist in

stabilizing the building. During an earthquake, the devices work

like giant car shock absorbers to slow the floors' movement.

The dampening

device used in the San Francisco civic center and many other structures

involves a cylinder filled with oil. Engineers design these devices

so that when one end of the cylinder is pushed, the oil moves.

The oil's temperature increases when it moves, converting much

of the energy that would have shaken the building into heat.

Scientists

have been working on advanced versions of these systems that would

respond to measurements taken during an earthquake and adjust

almost instantaneously to the particular characteristics of those

ground movements. Various technical difficulties have prevented

these systems from being used to help protect structures, Constantinou

said.

--

By Karyn Schwartz, Online NewsHour

|