Journey Indiana

Instrumental in Indiana: The Story of Fox Products

Clip: Season 7 Episode 3 | 6m 7sVideo has Closed Captions

Fox Products makes world class musical instruments right here in Indiana.

Travel to Fox Products in South Whitley to learn the story behind the world class musical instruments made right here in Indiana.

Problems playing video? | Closed Captioning Feedback

Problems playing video? | Closed Captioning Feedback

Journey Indiana is a local public television program presented by WTIU PBS

Journey Indiana

Instrumental in Indiana: The Story of Fox Products

Clip: Season 7 Episode 3 | 6m 7sVideo has Closed Captions

Travel to Fox Products in South Whitley to learn the story behind the world class musical instruments made right here in Indiana.

Problems playing video? | Closed Captioning Feedback

How to Watch Journey Indiana

Journey Indiana is available to stream on pbs.org and the free PBS App, available on iPhone, Apple TV, Android TV, Android smartphones, Amazon Fire TV, Amazon Fire Tablet, Roku, Samsung Smart TV, and Vizio.

Providing Support for PBS.org

Learn Moreabout PBS online sponsorship♪ >> Building musical instruments is a really interesting mix of modern technology and old-world craftsmanship.

It's a lot of highly skilled artistic people.

It is wood turning, and it is jewelry making, but it's -- it's also manufacturing.

So we're trying to do it efficiently and at scale.

>> The story of Fox Products begins with Hugo Fox, a native Hoosier and a bassoonist with the Chicago Symphony for nearly 30 years.

♪ >> And upon retiring from that position, he moved back to South Whitley, where he was born and raised to the Fox family farm, which is the property we are on today.

>> For most of his career, Hugo played a Heckel bassoon, made in Germany.

In the 1940s, and for decades prior, there were no bassoons made in the United States.

Hugo's dream, world-class instruments made right here in Indiana.

>> I like to envision him just sitting at his kitchen table, looking at his bassoon and thinking, you know what, I could do this.

I could pull this off.

And it took him two years to make the first instrument.

All in rather humble surroundings.

>> He actually converted one of the farm's chicken coops into the first manufacturing setting for Fox Products.

>> But after nearly a decade of production, Hugo's health began to decline.

In the early '60s, his son Alan returned to South Whitley to learn and ultimately grow the family business.

During Alan's tenure, which lasted more than 50 years, Fox expanded into international markets, built a new factory, and developed their first contrabassoon, oboe and English horn.

>> Alan incorporated all the product families that we currently produce and really grew the company exponentially.

>> In 2012, Tony Starkey, a fellow South Whitley resident and business owner, acquired Fox Products.

And in 2024, Fox celebrated 75 years of manufacturing instruments for a variety of customers.

♪ >> We have brighter sounding instruments; we have darker sounding instruments.

And those words themselves mean different things to different people.

But we have instruments that offer different results in terms of sound concept.

♪ There's also the different levels of player.

So a student needs just a real stable instrument that's gonna respond and gonna help them become a good player quickly.

And a professional probably needs something that has a lot more flexibility where they can play with the tone color, they can play with the pitch if they need to.

And we can accommodate all those things with our various models.

>> All the instruments made at Fox, bright or dark, student or professional, have a common starting point.

>> We get in raw materials.

We get in wood that is going to be the body of the instrument, and we get metal that is going to be on the keys on the instrument.

>> From these simple raw materials, things get, well, complicated.

>> There might be five people who touch any individual single key component, and that little key component is going to go into a subassembly that is what a person would call a key, and probably two to four people touch that.

And all of that times 40-some odd keys.

And then it takes at least a dozen people to do the finishing process.

So it's many hands and many hands multiple times.

>> And the real magic at Fox is in all of these hands.

In the hands drilling tone holes, the hands making bocals, and in the hands doing the final play testing.

♪ >> Everybody on our team takes a lot of pride in what we do, and they take a lot of pride in the part that they are playing in, something that's world-renowned like our products.

So it's something that's really engrained in the DNA, and it speaks to the high caliber of people on our team, and just their overall dedication to the quality and the mission of providing the most high-quality instruments to the music industry.

>> The team at Fox is around 140 strong.

And while many are focused on traditional instrument building skills, an increasing number are transitioning to more modern methods.

>> The process has changed dramatically since I've been here for the last 18 years.

We are automating so much more.

There's so much more precision and control due to the introduction of CNC mills and lathes.

>> A more recent expansion brought Fox's silver plating in-house.

>> And that's actually the facility that my father owned in his previous business venture.

So it's kind of coming full circle.

I remember riding my scooter around there when I was a kid and shooting baskets and all that.

So it's been pretty fun to have that facility back in the fold.

Our business strategy is to put our arms around just as much as possible so we can really control the outcome and the quality.

So silver plating was a daunting thing for us to bring online, but we have a really dedicated crew that has worked their tail off to dial that in, and we are really happy with that decision.

>> 75 years and counting, tens of thousands of instruments built, and countless musicians challenged and inspired.

All right here in South Whitley.

>> It's amazing, the transformation the company has made since starting out in a chicken coop to where we are today, and it also speaks to where do we want to take it in the future.

For a company likes ours to be around for 75 years, and to be still a small family-owned business, really takes a constant evolution of not only how we do, but also what we do.

Art of the Ancestors: How Connecting with Mexican Traditions Helped Emily Guerrero Heal

Video has Closed Captions

Clip: S7 Ep3 | 5m 55s | Emily Guerrero creates large public art exhibits known in her Mexican culture as ofrendas. (5m 55s)

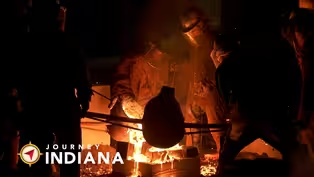

Casting Community: Artists Learn Iron Pouring at this Annual Southern Indiana Workshop

Video has Closed Captions

Clip: S7 Ep3 | 6m 40s | Each Summer, an Indiana workshop lets young artists design and pour their own cast iron sculptures. (6m 40s)

Top of the Pops: Amish Country Popcorn Helps Keep Indiana #1 Producer

Video has Closed Captions

Clip: S7 Ep3 | 3m 42s | When it comes to popcorn Indiana is #1! Why do we still love this snacking staple? (3m 42s)

Providing Support for PBS.org

Learn Moreabout PBS online sponsorshipSupport for PBS provided by:

Journey Indiana is a local public television program presented by WTIU PBS