We Got it Made: Manufacturing in the Carolinas | Carolina Impact

Clip: Season 12 Episode 1222 | 6m 22sVideo has Closed Captions

Manufacturing isn't gone but it's changed. We take a look at 4 companies making things here in NC.

The hum of industry has long been the heartbeat of the Charlotte Region. What began with textiles over a century ago has evolved into a powerhouse of innovation. Today we take a look at Carrier Heating and Cooling, Meridian Specialty Yarn Group, Wooltribe, and Jalilude Embroidery who continue to redefine what’s possible in modern manufacturing.

Problems playing video? | Closed Captioning Feedback

Problems playing video? | Closed Captioning Feedback

Carolina Impact is a local public television program presented by PBS Charlotte

We Got it Made: Manufacturing in the Carolinas | Carolina Impact

Clip: Season 12 Episode 1222 | 6m 22sVideo has Closed Captions

The hum of industry has long been the heartbeat of the Charlotte Region. What began with textiles over a century ago has evolved into a powerhouse of innovation. Today we take a look at Carrier Heating and Cooling, Meridian Specialty Yarn Group, Wooltribe, and Jalilude Embroidery who continue to redefine what’s possible in modern manufacturing.

Problems playing video? | Closed Captioning Feedback

How to Watch Carolina Impact

Carolina Impact is available to stream on pbs.org and the free PBS App, available on iPhone, Apple TV, Android TV, Android smartphones, Amazon Fire TV, Amazon Fire Tablet, Roku, Samsung Smart TV, and Vizio.

Introducing PBS Charlotte Passport

Now you can stream more of your favorite PBS shows including Masterpiece, NOVA, Nature, Great British Baking Show and many more — online and in the PBS Video app.Providing Support for PBS.org

Learn Moreabout PBS online sponsorshipThe hum of industry has long been the heartbeat of the Charlotte region.

What began with textiles over a century ago has evolved into a powerhouse of innovation.

"Carolina Impact's" Chris Clark takes a look at a few of the businesses that continue to redefine what's possible in modern manufacturing (graphics whooshing) (gentle music) (button clicking) - [Chris] Towns claim to their past like old t-shirts, famous for things they don't actually do anymore.

Bethlehem, Pennsylvania hasn't made steel in years.

In Hershey, Pennsylvania, the sweet smell of chocolate is more nostalgia than production.

And in Roswell, New Mexico, well, let's just say the aliens left a long time ago, but the souvenir shops did not get that memo.

But Charlotte is still rooted in what it does and what it's becoming.

- We've continued to evolve.

- You can come here and get everything you need.

- [Chris] The region's manufacturing roots run deep starting with textiles over a century ago.

Today, it's home to more than 3,500 manufacturers employing 146,000 people, including major players like Carrier, known best for heating and cooling.

Opened in 1999, this massive 374,000 square foot facility homes with purpose.

Here, they build air and water cooled chillers capable of taming the heat with cooling power spanning 50 to 5,500 tons to place where engineer to order solutions take shape destined to serve customers across the globe.

- I'm very proud of the fact that our organization has thought ahead of its time.

Many of our solutions designed, manufactured, built here are running millions of tons of air conditioning all over the world.

- [Chris] Carriers mastered the art of refreshing iconic places, for Madison Square Garden, the Beijing's National Stadium.

But when tasked with preserving Michelangelo's masterpieces and the Sistine Chapel, the challenge took on divine proportions.

- It's enormous and it's a matter of pride for us.

There are so many verticals.

ADVANTEC Group really puts the entire system lens together, not just one equipment.

Juxtapose that with process cooling where we have very high tech data center solutions.

- [Chris] The carrier facility is just one example of the region's manufacturing evolution.

Formerly home to a booming textile industry, Charlottes Mills were once the heartbeat of the local economy.

Though many have fallen silent.

The Meridian Specialty Yarn Group evolved and endured a testament to its resilience.

- You don't have to have all these different facilities that you have to pay for shipping and coordination with all the different individuals and all of their different styles.

- [Chris] Running at capacity, they can spend 80,000 plus pounds a week with the flexibility to spin acrylic, nylon, silks, alpaca, and of course, wool.

- We have to accept wool that is clean, carded and combed, and it's called top.

It's giant, 80 pound bumps that are just kind of coiled into a donut.

We just put it into our preparation equipment and we start to draft it to prepare for our spinning.

- [Chris] Alongside the massive industrial runs, the team also works closely with smaller scale designers crafting custom batches of yarn with the same level of care.

For many of their clients, this isn't just a product, it's a piece of who they are.

- With this market, it's a lot about emotions.

It's a lot about their heart and because they are pouring, this is their art.

This is how they express themselves.

We knew if we did not do this correctly and did not fix problems that we did see, we would lose that market.

- [Chris] A few minutes down the road, the yarn lands and studios like WoolTribe.

The business started after a lackluster experience on a road trip.

- Yeah, it was.

- We want it's...

I'll tell you what it was exactly.

You wanna... - Yeah.

- Like, if you're a woodworker and you walk into a place, you wanna walk in and go, "Wow."

You wanna feel inspired and we just weren't feeling that.

- [Chris] So the pair did what entrepreneurs do and open their own yard shop.

Soon, they literally had their fingers in dye pants creating their own signature color yarns.

At first, it was all about the fiber, not finished goods.

But then something unexpected happened, customers weren't just admiring the yard.

- You see the beanies on the mannequin on the heads?

- Yeah.

- And then sweaters and everything.

- Yeah.

- So they're called samples.

And that sells yarn, that sells patterns because customers, knitters, crocheters would see it and go, "Oh, okay, I want that pattern."

So the non-knitter would come in and say- - That would come in with the knitters.

- "Oh my God, that sweater's beautiful."

Can I buy that?"

- "Can I buy it? "

- No.

- [Chris] With a little help from Master Knitter Jeanne Carver sketching out the pattern, it didn't take long for wool drive to stitch together a hat and scarf combo that's as stylish as it is homegrown.

- We've purposely focused on American fiber and knowing who our supply chain partners are and really working with them to create a community more than just product.

- [Chris] The hats are a one of a kind piece of wearable art but not finished yet.

A final stop in their journey isn't minutes away, but rather seconds.

Literally around the corner where Jalilud Embroidery sows their custom labels.

(machine clattering) Opened in 2022, the business was a leap of faith.

After 20 years as an embroider, Janeth Flores was laid off and decided to bet on herself with her own venture.

- It was really scary at thirst to be honest, but I mean, I didn't wanna go back to work for someone else.

- [Chris] With 60 machines she clears roughly 250,000 annually, she could put just about anything on a garment and the WoolTribe patches are unique.

They require a multi-step process that begins with stitching the logo onto a piece of leather.

Each one tailored with precise color-specific detail.

- To be honest, we don't do patches.

It's just for them.

(chuckles) They're our only customer that we do the patches.

- [Chris] Leather gets cut down then sewn on the garment.

It's an extra step but worth it for the people it's made for.

- That's really important for me because, of course, I love the people support us.

- [Chris] From textiles to heavy machinery, automotive parts, plastics and biomedical manufacturing thrives across our region.

With the southeast lowest corporate tax levels and top rankings for business and competitiveness, north and South Carolina remain places manufacturers like to call home.

For "Carolina Impact", I'm Chris Clark.

(upbeat music)

A City in Color: David French's Connection to Charlotte | Carolina Impact

Video has Closed Captions

Clip: S12 Ep1222 | 5m 9s | David French connects with Charlotte’s community through vibrant art and collaboration. (5m 9s)

Laughs for All with Thomas Heynen | Carolina Impact

Video has Closed Captions

Clip: S12 Ep1222 | 5m 22s | A Charlotte man uses comedy and sign language to make people laugh. (5m 22s)

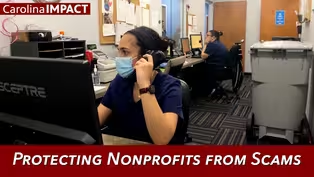

Protecting Nonprofits from Scams | Carolina Impact

Video has Closed Captions

Clip: S12 Ep1222 | 6m 27s | Helping non-profits with cybersecurity efforts. (6m 27s)

April 15, 2025 Preview | Carolina Impact

Preview: S12 Ep1222 | 30s | Manufacturing in the Carolinas, Protecting Nonprofits, Comedian Thomas Heynen, & Artist David French (30s)

Providing Support for PBS.org

Learn Moreabout PBS online sponsorship

- News and Public Affairs

Top journalists deliver compelling original analysis of the hour's headlines.

- News and Public Affairs

FRONTLINE is investigative journalism that questions, explains and changes our world.

Support for PBS provided by:

Carolina Impact is a local public television program presented by PBS Charlotte