Chicago Works

Special | 56m 41sVideo has Audio Description

Chicago is known as the city that works. Geoffrey Baer explores the city’s unique jobs.

Chicago is known as "the city that works." The inhabitants of the "City of the Big Shoulders," as Carl Sandburg described it, are widely regarded as hard-working, tenacious, and resilient with a well-deserved reputation for Midwestern friendliness and approachability. Explore some of the city’s most unique jobs with Geoffrey Baer. Audio-narrated descriptions of key visual elements are available.

See all videos with Audio DescriptionADProblems playing video? | Closed Captioning Feedback

Problems playing video? | Closed Captioning Feedback

Chicago Tours with Geoffrey Baer is a local public television program presented by WTTW

Chicago Works

Special | 56m 41sVideo has Audio Description

Chicago is known as "the city that works." The inhabitants of the "City of the Big Shoulders," as Carl Sandburg described it, are widely regarded as hard-working, tenacious, and resilient with a well-deserved reputation for Midwestern friendliness and approachability. Explore some of the city’s most unique jobs with Geoffrey Baer. Audio-narrated descriptions of key visual elements are available.

See all videos with Audio DescriptionADProblems playing video? | Closed Captioning Feedback

How to Watch Chicago Tours with Geoffrey Baer

Chicago Tours with Geoffrey Baer is available to stream on pbs.org and the free PBS App, available on iPhone, Apple TV, Android TV, Android smartphones, Amazon Fire TV, Amazon Fire Tablet, Roku, Samsung Smart TV, and Vizio.

Chicago is known as "the city that works," but who keeps it working?

I'm Geoffrey Baer.

Now, if you've seen my shows over the years, normally, you see me.

But if you stood where I'm standing, this is what you would see, a whole crew of people behind the scenes who make the show and me look good.

Thanks everybody.

And that got me thinking.

(bright uplifting music) You ready?

(flames sizzle) (bat pings) [Geoffrey] There are people behind the scenes In all aspects of our daily lives.

This whole place was shaking.

This is gonna come down.

The bridge is going up.

That is wild!

[Geoffrey] People we almost never see.

Back up!

Oh my gosh.

In this show, we'll meet them.

When I am a big girl, I'm gonna do that job.

So it's kind of special.

It's a lifestyle.

It's our lifestyle.

[Geoffrey] And discover the amazing work we mostly take for granted.

After a while, you just don't smell it anymore.

One, two, three, four.

Action!

(fire exploding) When you love what you do, it never gets boring.

So come along with me, and all of us, as we show you how "Chicago Works".

Lead support provided for "Chicago Works with Geoffrey Baer" is provided by: Lead corporate support is provided by: Major support is provided by: Additional support is provided by these donors: (engine roaring, tires screeching) (bell dinging) They've starred in movies, they tie up traffic, they're historic.

There might be nothing more iconic than the Chicago River Bridges.

Let's see who makes 'em go up and down.

It takes a whole team to lift a bridge, but Joan Welsh has the best view.

She operates the controls three stories up in a bridge house.

(bell dinging) [Dispatcher] Go ahead, Joanie.

I'm gonna get started up here.

[Dispatcher] Roger that.

Okay?

Yeah.

Everybody, please be careful on the stairs.

There might be grease.

[Geoffrey] While Joan prepares to open the bridge.

Watch your step.

Foreman Joe Hosty heads three stories below street level to manage the monstrous machinery that moves it.

This is gonna come down.

The bridge is going up.

Oh, it's like they're moving like a teeter-totter.

(wheels whirring) (bell dinging) And there it goes.

That is wild!

(bright music) At Joan's command, 1500 tons of metal and concrete make way for seven sailboats traveling from their winter dry docks to lakefront harbors.

How long have you been doing this?

28 years.

What did you do before you did this?

That's funny, I was a cashier at Jewel.

10-4, bringing 18th street down.

(gears turning) Joan's transition from supermarket to super-sized bridges took a year of training.

So are all the bridges identical and opened the same way?

No, very much different, no.

Some were built in the 1800's, some in the 1900's.

(metal clanks) That's a nice landing right there.

That's a nice landing.

That's what we want.

You can hear that just like woo.

That's what we want.

[Geoffrey] So you're proud to be a Bridge Tender.

Oh, very proud.

You know, I was just happy to get a Chicago job at the time.

[Geoffrey] Yeah.

And now, all these years later, I realize what a unique, cool gem of a job I fell into.

(Geoffrey chuckles) (bell dinging) This type of bridge is called a trunnion bascule bridge, and it's a big improvement over earlier bridge types.

The first river bridge built in 1834 at Dearborn Street was a hand cranked contraption.

It got stuck so often that a mob of angry of residents demolished it.

Swing bridges that pivoted around a post in the river, forced vessels to squeeze by on either side.

In 1863, the Rush Street swing bridge swung open with a herd of cattle on it.

(cattle mooing) The bridge collapsed, dumping the cows into the filthy river.

(bell dinging) Kevin Seggerson directs the roving crews who leapfrog from one bridge to another as those seven sailboats continue on their journey.

(bell dinging) (cars whooshing) (horn honks) You're blocking traffic for hundreds and hundreds of cars for seven sailboats.

Sometimes one sailboat.

So is that like some sort of federal law?

That boats have the right of way?

Yes.

Even one sailboat?

Yes.

[Geoffrey] For a hardworking crew trying to keep on schedule, the landmark DuSable Bridge at Michigan Avenue can be irksome because it's usually packed with shoppers and tourists.

(bell dinging) [Kevin] The operator's always yelling out the windows at this one.

[Geoffrey] Oh really?

Yeah, these people just don't stop here.

[Geoffrey] They just keep walking.

Yeah.

Back up!

Yeah, look at that, they're just standing there on the bridge.

They'll get a surprise if it starts going up.

Everybody off the bridge!

(laughs) (bright music) Did you ever think you'd be doing this job?

No.

No, but when I got it, I kind of fell in love with it.

It's one of those jobs that when you tell people you're a Bridge Operator, you're doing something that not many people know.

I mean, there's 27 bridges that we operate down here.

So to be one of these people that can operate these bridges, it's kind of special.

Hello.

[Geoffrey] Hi.

Oh, thank you.

Thank you, you have a good one.

I sure will.

You know, in these days of e-commerce, most of us get packages delivered to our front stoop all the time.

One of the biggest shippers, UPS, allowed our cameras to capture the most amazing five minutes of a package's journey.

(bright music) It happens here in south suburban Hodgkins, Illinois at the largest UPS ground sorting facility in the country.

This is where packages arrive from far and wide, are sorted, and are sent on their way.

This staggering facility employs 7,000 people and covers 1.5 million square feet.

We have 9,000 conveyors, about 60 miles worth of conveyors, are in this building.

60 miles!

That's Aaron Duell.

He's in charge of the automation that helps every package find its way from the trucks that bring them in, to the trucks that send them on their way.

Every package really should take, on average, about five minutes from the time it's unloaded until the timing goes into the trailer.

Five minutes?

Five minutes.

Wow.

But I'm seeing like baby strollers and a barbeque.

Each one of these is built like a story to me.

Every one of 'em is a story.

When we talk to our employees, we say they could be cookies going to grandma, or you know, a piece of artwork, or it could be insulin going to somebody with diabetes.

To move packages through this massive, mostly automated system in just five minutes, it takes an inventive team of tinkerers like Aaron.

How did you train for this?

Did you go to school for this?

I went to school for engineering.

So when you were a kid, were you always like building tinker toys?

If a toaster broke, I would tear it apart, look at the insides and try and figure out how to fix it and put it back together.

[Geoffrey] Oh, yeah.

And how our packages end up in the right trucks is a head-spinning process that only an engineer could explain.

So right now, we're taking all the packages that have come off of our unload.

They've already gone through a singulator, And they're... A singulator?

Time out.

These UPS folks speak a language of their own.

I need a translation.

They've already gone through a singulator.

And they're...a singulator?

[Aaron] Well, a singulator just makes sure that they're not side by side.

[Geoffrey] Ah, okay.

[Aaron] Makes sure that they're spaced so that while they progress through this tunnel, This tunnel is going to wind up reading the UPS label.

And it's gonna use that information to identify what load we're gonna divert to downstream.

So these things are then getting shoved into the trucks?

I wouldn't say shoved, I would say gently moved.

(Geoffrey and Aaron laughing) 10-9-A, sort belt photo eye block, 10-9-A sort belt photo eye block.

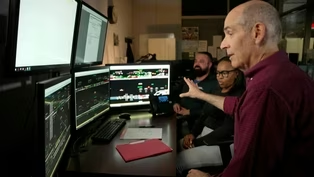

With hundreds of thousands of packages flowing throughout the building, eagle-eyed supervisors have to problem solve as quickly as possible.

So what are all these people doing in here?

Well, they monitor all the systems That make it happen, right?

This is what you call the control room.

These folks are making sure that the computer is running entirely from inbound all the way to the outbound.

After packages are sorted into as many as 1,000 outbound semi-trailers, they hit the road for destinations all across the country.

So next time you get a package from UPS, think about the frenetic five minutes it's spent in a hub to help it find its way to your doorstep.

Perfect.

Let's head to the friendly confines.

(bright music) Just like at every other ballpark, The hardworking grounds crew at Wrigley Field mows the grass, grooms the infield dirt, and stripes the field.

But Wrigley Field might be the quirkiest ballpark in America.

So here, the grounds crew takes care of a few other things (bat pings) (audience cheer) like an outfield wall covered in ivy, or a scoreboard from 1937 still operated by hand.

In this age of electronic razzle dazzle, workers inside the old scoreboard still keep fans informed the old-fashioned way.

And there's really only one way to learn how it's done.

I'm inside the scoreboard.

In here, workers update the score of the Cubs game in real time, along with scores of all the other major league games in progress, scrambling up and down catwalks on three levels, each with three rows of scores under the watchful eye of the Chairman of the board, Darryl Wilson.

This is a lot of work.

Oh yeah, man.

[Geoffrey] How long you been doing this?

I've been up here since 1991.

[Geoffrey] Was this like a dream come true to do this?

Well, when you start in the ground crew, You start off with tarp, rain delays, rolling out the tarp.

[Geoffrey] Getting soaked got old after a while.

So when a scoreboard worker retired, Darryl jumped at the chance to work inside and stayed dry.

How many people are in here now?

[Darryl] Five, we got five people.

You wanna do it?

Oh, absolutely.

Just take this.

This is for the upper games.

You're gonna pull it, and you're gonna turn it around.

Okay, so that's a zero.

Yep, so you flip it.

That's okay, yep.

Set it in there.

So there in the bottom of the eighth.

Push it up.

You're good, now, lock it down.

You might have to push on it.

[Darryl] A little tighter.

There you go.

Did it!

You don't know if it's upside down.

You know, you can make a mistake.

We have done that before, so... You have?

Oh yeah, I had 2's upside down, skipped innings... You know, but you don't know.

You're moving around so fast.

Yeah, and it's backwards too.

And it's backwards, right?

Oh yeah, you gotta be careful about that too.

Now, I'll just slide my left finger over to whether it'll be three balls or two strikes.

[Geoffrey] One scoreboard worker isn't in the scoreboard.

He's up in the press box, "Quick" Rick Fuhs, the fastest finger in baseball updates the balls, strikes and outs, the instant the ump calls them.

Although my fingers are nowhere near as fast, Rick did allow me to put up the number of a new batter stepping up to the plate.

And his number is 13.

Hit the one, and then hit the three.

You see how... [Geoffrey] Hey, there it goes!

See how fast it goes out there like an instant, right?

[Geoffrey] When the Cubs aren't playing, Quick Rick slows down to lovingly care for another unique feature of Wrigley Field.

Now, I've got some clippers for you right here.

Oh, nice.

Try to cut it on this brick line here.

Oh, right on the line.

So I pull it out, yeah, I pull it out a little bit.

Watch your finger.

Yeah, you don't do this at other ballparks in America.

The famous ivy on Wrigley's outfield wall was the brainchild of another Chicago baseball legend, Bill Veeck.

Bill Veeck.

We know Bill Veeck as the owner of the White Sox.

Yeah, he worked there though.

He worked under P.K.

Wrigley there.

[Geoffrey] At the Cubs?

Yep, he was 23 years old.

He was the architect of putting this ivy up.

Back in the 1930's, Veeck was helping Cubs owner P.K.

Wrigley realize his vision to make his stadium almost park-like.

Is this the ivy from 1930's?

They haven't ever replanted it.

We've done some replanting - in troubled spots, But this is the original ivy from 1937.

[Geoffrey] Because of the ivy, there are some special ground rules at Wrigley.

So if the ball goes in the ivy, the outfielder have to raise his hands up.

You raise, literally - raise your hand.

Yeah, raise his hands up, said, "I can't see the ball."

It's a ground rule double.

That is the only ball park in America where you got a rule like that.

But if he touches the ball, if he touches it, it's in play.

Still in play?

Yeah.

Even if he's like trying to get it out of the ivy.

They may never swing a bat or catch a ball, but Rick and Darryl have been part of some of Wrigley's greatest moments.

Were you up here for the World Series?

Yeah, oh yeah.

[Geoffrey] How did that that feel?

I was going nuts.

The energy was so strong, this whole place was shaking, and the scoreboard was rocking actually.

[Geoffrey] Maybe the best job of all is another tradition that dates from an earlier era, flying the W after a Cubs win.

Hold on the ropes, waiting for that last out.

And the thing is to get it before the song says, "Go Cubs go..." [Geoffrey] They don't like to see the L. Oh, no, no, the L, it's like a funeral home in here, it's quiet.

And you don't have to rush to do the L. You can take your time.

(dramatic music) (calm music) Just hanging out with the guitar fish here and the sharks.

The Shedd Aquarium is one of the most popular attractions in Chicago.

This is what two million people a year see.

Let's check out what they don't see.

As the sun rises, hours before guests arrive, it's breakfast time for the Shedd Aquarium's beluga whales, and they have big appetites.

Senior Trainer, Angie Soliai makes sure each whale gets exactly the right amount of their favorite frozen seafood.

Who's this for?

This is for Kimalu.

Kimalu, okay.

Right in there.

Perfect, we are gonna do herring for Annik, and he gets 10 kilos.

[Geoffrey] Wow.

You definitely have to not mind fish smell, right?

I mean, after a while, you just don't smell it anymore for sure.

It's a squid (chuckles).

Oh my gosh.

I'm gonna have nightmares.

(bright music) Now comes the fun part.

There you go.

There you go.

All right, here, just take the whole bunch there.

There you go.

Very nice.

[Geoffrey] Michele August is one of many Shedd trainers who spend hours each day.

[Michele] All right, how we doing?

[Geoffrey] Bonding with the belugas.

(beluga calling) They understand what we're asking based on how we move our hands and bodies.

Oh my gosh.

Nice job buddy.

Do you wanna try giving him a hand signal?

What do I do?

You're gonna take your right hand, and you're gonna pretend like you're pulling down on a string, okay?

Okay.

All right.

Right now?

Go ahead right now.

(beluga whale buzzing) (Geoffrey laughing) Yeah, good job.

Oh my gosh (laughs).

Very nice, very nice.

Now, that's not just for putting on a show, right?

Right, our number one reason for training them is so that we can take better care of them.

So in a position like this, if you wanna step forward a little bit more.

Okay.

- I'm gonna tip him on his side.

So in this position, we could actually do a voluntary ultrasound exam.

[Geoffrey] Belugas are - salt water creatures, But the Shedd sits on the shores of Lake Michigan.

So where do you get millions of gallons of salt water when you're 800 miles from the nearest ocean?

Well, back when the Shedd opened in 1930, Saltwater was imported from Key West, Florida on railroad tank cars.

They ran on a dedicated track through what is now the museum campus.

Today, the Shedd makes its own seawater using the same product you can buy in pet stores, except they buy it in one ton bags.

Operator, Maurice Smith makes 9,000 gallons a day.

That's a hazard of the job, right?

Yes, it is.

[Geoffrey] So you don't have high blood pressure, do you?

No.

[Geoffrey] It is a bad job for somebody with - high blood pressure.

Yes it is, yes it is.

It's much salt.

You have an aquarium at home?

[Maurice] Yes.

[Geoffrey] You do?

Yes.

Well, that's why kind of, I was happy to come here Because I've had aquarium since I was a little kid.

[Geoffrey] Oh really?

Yeah, since I was like about 5 or 6, My dad brought a tank home, and I've been in love with fish ever since.

So coming here was like a dream.

When we change water from a fish system, we can send it To the ocean area.

Maurice also monitors the computers that control a huge network of pumps and valves distributing that sea water throughout the aquarium.

Just like the Shedd's visitors, these aquatic animals have no idea about all the systems behind the scenes that allow them to thrive, but they do know those curious human creatures who shower them with love and food every day.

Have you always been interested in animals?

Absolutely, yeah, I was definitely an animal person from the very beginning.

[Geoffrey] You seem to just love... I do, there's nothing quite like them.

It's very special.

(uplifting music) (train horn honks) - If you ride Metra trains, you probably spend most of your time just looking at your phone or looking out the window, And you might never think about who it is that's getting you from point A to point B. Well, it takes a whole team, starting of course, with the engineer up front.

(mellow music) At the start of a run, Engineer Rob McGuire follows the track signals sent by distant controllers who guide the train out of Union Station.

All right, now we're coming out into the daylight.

Did you always wanna be a train engineer?

No.

[Geoffrey] No?

No.

[Geoffrey] Oh, that's funny.

Yeah, I'm third generation on both sides of my family That worked on the railroad, and they encouraged me not to go into railroading.

(Geoffrey laughs) So welcome to Metro CCF.

We're the consolidated control center.

Now, here's a guy who loves working on the railroad.

Greg Godfrey supervises the control center that directs 700 Metra trains each day across 11 commuter lines.

So every day at Metra, we operate 9,794 switches and signals.

Approximately.

Approximately, and every 10.14 seconds, somebody's either throwing a switch or operating a signal.

Trains don't have steering wheels, So we're essentially the steering wheel for the train.

They're throwing switches?

Everybody here is throwing switches and signals remotely across hundreds of miles of Metra's railroad network.

This is the Rock Island district.

This is just one line?

This is just one Metra line.

That's Assistant Chief Dispatcher, Lorna Wilson-Phillips.

And that's Rock Island train 407.

So he's going across.

[Geoffrey] Ooh, now he's there, oh, look there.

[Lorna] He just took this signal.

Now, as a lover of trains, I have to say these computer screens are a little bit less romantic than the technology railroaders used in days gone by like this.

(levers clanks) But this isn't a museum.

We're at Tower A2, which controls the busiest rail intersection in the Midwest.

This looks pretty old school.

When is this from?

This was made in the early 1930's.

Now, why not just replace this with some other technology?

Well, the problem is, is the complexity of traffic patterns that exist here at Tower A2.

[Geoffrey] This section of the Metra system is so complex, there's never been enough funding to modernize it.

But this tangle of tracks and the old machine that controls them are living reminders of Chicago's railroad history.

Chicago's first train line opened in 1848 with one secondhand steam engine.

Within 10 years, train lines extended in every direction from Chicago, and the city was the undisputed rail capital of America, and it still is.

Approximately 1,300 trains travel to, from, or through Chicago every day carrying 175,000 passengers and 25% of America's rail cargo.

Rob has finished his run, but his long day isn't over yet.

(cables snap) Between trips, engineers take their trains out to the yard For a little TLC.

So it's just like working your car at a gas pump.

[Geoffrey] These locomotives don't get miles per gallon.

They burn about four gallons per mile.

[Rich] So the larger locomotives hold about 2,400 gallons of fuel.

[Geoffrey] Yeah, so do you use a credit card?

(Kevin and Rich laugh) Yes, his.

We're going through the train wash now.

Just like when you wash your car.

Did you pay extra for the wax treatment?

[Rich] No.

[Geoffrey] The undercarriage wash?

Before long, Rob and his train are ready for another run.

Why do you think kids like trains so much?

I don't know, that's probably a question for a child psychologist.

I don't know.

(Geoffrey laughs) I'm baffled by why people love trains so much (laughs).

Did you like trains when you were a kid?

Absolutely.

When the freight came through the city, I would run alongside, and I used to say all the time, "When I'm a big girl, I'm gonna do that job."

Really?

Yeah, I did.

[Geoffrey] You always knew you wanted to do this.

I did, I love it.

When you leave a busy day here, you're like, "Look at all that I managed.

Look at what we did.

We moved X amount of trains, we moved X amount of equipment and everybody went home safe."

That is a good day.

A good day at work these days often involves jobs people 100 years ago couldn't have imagined, and a lot of the jobs they did back then don't even exist anymore.

Before electric streetlights, lamplighters lit gaslights by hand each evening and extinguished them in the early morning hours.

The last gas streetlights in Chicago weren't eliminated until 1954.

Before mechanical refrigerators, ice men brought blocks of ice cut from local lakes in winter for use in home ice boxes.

Before the dial telephone was invented, switchboard operators, mostly unmarried White women, manually patched through local and long distance phone calls.

Before automobiles ruled the road, there was plenty of work shoveling horse manure into underground manure vaults in Chicago alleys.

And if you wanted a fancy sign in your shop window, you had to hire a skilled artist to paint it by hand.

But wait, that job is making a comeback.

They say signs are one of the oldest professions.

One of the two.

One of the two.

(all laugh) The second oldest profession.

Oldest.

[Geoffrey] This flashy technique Of solid gold sign painting was pioneered in Chicago.

But it almost became a lost art until Andrew and Kelsey McClellan came along.

We had painted signs back in Denver.

And then when we came out here for school is when we got introduced to the gold leaf signs, All the gold leaf in the Loop, and we were just enamored with it.

It was like, almost like magic to us.

I noticed a signature on one of 'em.

And so I googled him.

Kelsey's search turned up one of the last gold leaf sign painters, Robert Frese, who defied the trend of gilder's guarding their secrets and took the young artists under his wing.

Were you worried that this was just gonna die?

Yeah, I was worried that I would be the last generation and it'd be completely gone, yes.

And I'm really proud of 'em.

I mean, they're doing phenomenal work now.

[Geoffrey] Robert taught the McClellans to make gold leaf signs in a way that's particular to Chicago.

Chicago style gilding is essentially the convex effect on letters where it gives it kind of that 3D look, that was popularized here at the turn of the century.

There wasn't really electricity widespread at that point.

And so they were the brightest signs.

With the reflection, it was just very attractive.

Fortunately, the McClellans proved their mettle in handling this valuable and fragile material.

Ooh, oh, I just knocked some off.

[Andrew] Don't worry.

Don't worry, this is just a sample.

[Geoffrey] Oh, look at that.

You could like rub it in between your hands And it would just disappear.

Really?

To start, Andrew makes a stencil using a gadget I would never come near.

This machine right here is called an electro pounce.

It essentially electrocutes little holes into the paper.

You don't wanna accidentally touch yourself with it.

It is very unpleasant.

[Geoffrey] Whoa, oh my gosh.

And this is for what kind of store?

This is for a record store.

[Geoffrey] Once the stencil's done, the work moves on site.

And we're gonna transfer the design onto the glass.

So there you go, you're laying it on.

Now, look at it, just jumps onto the window.

I thought he was not as good at this as you are.

[Kelsey] Oh no.

[Geoffrey] But you're trusting him to do a whole window on his own.

He'll probably do better than me.

(Kelsey and Geoffrey laugh) Anything that goes outside of where the area we want it to be gold, we'll just clean off.

[Geoffrey] So why did you wanna have a hand-painted sign on your window?

It was one of the things I was drawn to was the fact that it's part of the history of Chicago.

And now that they are doing this, everywhere I look, I'm seeing the gold leaf signs.

(uptempo cheerful music) (Andrew) Signs make up a part of the visual landscape of a place.

The Chicago style of gold leaf is part of what makes Chicago beautiful.

We have a lot of pride in carrying on that tradition, which could have easily been lost.

All right.

So what client is this for?

(chuckling) There we go, wow.

(indistinct opera lyrics) It takes years of training for a singer to make it to Lyric Opera of Chicago.

But as talented as they are, they rely on a loyal crew backstage to fully bring their performances to life, starting with the hair on their heads.

So every wig that we've made lives right here.

So this is one that we would use if you needed to be in the court.

Oh no.

In a period piece.

Charlotte, off with their heads!

Period piece or not, each artist on Lyric's stage wears their own custom wig.

It's actually more efficient than styling hundreds of singers' hair before each performance.

So you are making this wig one hair at a time?

Yep.

Emily Young is one of seven full-time wig makers at the Lyric.

And then we do a little loop and then you just take it and you just start tying.

- Did you catch that?

Let's see it again in super slow-mo.

Emily estimates that a wig like this would take 100,000 individual hairs.

Imagine if you got paid by the strand?

Oh man, I would be rolling.

A dollar a strand you guys.

(Emily chuckles) (indistinct opera lyrics) When our job is done well, you don't notice us.

We're trying to fool everybody every time.

[Geoffrey] If you think the wig makers are experts at illusion, wait 'till you meet prop master Charlie Reilly.

So any kind of flower.

[Geoffrey] Over four decades, he's amassed a collection that would make a hoarder jealous.

At this point, he can supply just about anything an opera director might ask for.

The craziest stuff people ask me for, They're like, "I'm sure you don't have that."

I'm like, "I do."

[Geoffrey] Even the macabre.

Say something like a severed head, we have one.

Okay, ooh, it's heavy.

It is heavy.

Break a leg.

Oh, there it is.

Oh God.

Even at its most gruesome, Charlie has no regrets about his career choice.

I love this job.

It's become part of my family.

I spend more time here than I do at home.

Every major thing that's ever happened in my life happened while I was here.

With so many moving parts on stage and off, it takes a conductor to keep everyone working together.

Well, you see, in a way, I think the conductor is the one who can really create the magic at the opera.

Up to 3,200 people every night.

Maestro Enrique Mazzola is one of only three artists who've ever held the title of Music Director at Lyric.

This is what you're looking at while you're conducting?

Yes (vocalizing).

(Geoffrey vocalizing) That's those trumpets.

Yes, the famous Egyptian trumpets, yes.

So can you teach me a little conducting here?

Yes, of course.

So the fundamentals is that we have the one is always down in front of you.

The one, two.

Two, that way.

Three, four.

Three, four.

One, two, three, four.

Bam!

Bam!

Oh yeah!

Yeah, okay.

So there is no doubt.

While I wait to hear if I pass the audition, I have a request for the Masters of Illusion back in the wig shop.

Now, I'm a bald guy.

Yeah.

Can I have a wig?

I think we can make something happen.

All right, so the process that we do to have your head shape is called a head wrap.

You ready?

Oh yeah, don't put it over my mouth.

(laughs) No promises if you're good.

All right, this is weird.

Now, we draw your hairline so that we know.

I don't have a hairline.

Then we make it up.

So then we trace it.

There it is, my head.

Is this what you thought you were gonna be doing for a living?

Yeah, actually, well, maybe not so specifically, but... You always wanted to be a wig maker?

Well, in kindergarten, I told everyone I wanted to be a hairdresser, And it just kind of was an offshoot of that.

Okay, it's time for my fitting.

We take this guy.

(Geoffrey chuckles) Oh, oh, oh my God.

Oh, I feel like Ronald Reagan.

Ooh, I don't like it.

(Allison laughs) Well, face too old for hair this dark.

And just like it's on, it comes off.

Now I feel like myself again.

The drama at the Lyric Opera, that's make-believe.

But here's a real life story of good and evil, where the villain is the four-legged kind.

(rats squeaking) For years, the Orkin pest control company has branded Chicago, the "Rattiest City" in America.

We're gonna start in the end of the alley there.

Okay.

Josie Cruz says Orkin's claim is nonsense, just a marketing gimmick.

But she doesn't deny that Chicago has a rat problem, and it's her job to lead the centuries old battle against them.

So we're here in this alley because we had a request for it to be baited because there's been some rodent activity.

So someone, we're looking but someone saw rats here.

Well, yeah, and there's different reasons why there's rats.

That's one sound that you hear there.

A dog.

A dog.

If they don't pick up after the dog, then you're gonna have a problem.

I mean, I don't wanna get too graphic, but why?

Because they'll eat the dog poop, they'll eat it.

Oh.

Yeah.

Like a vitamin.

Yeah, it's good, it's protein for them.

[Geoffrey] And the biggest invitation of all to a rat party is an open trash container.

This, see this right here?

Oh, look at that.

This is prime example of the rats just coming in here.

Oh, and the bag is just there.

Yep, yep, that's just perfect.

And this is just a perfect spot for them.

And can a rat get in a hole like that big?

Yes, quarter size.

[Geoffrey] A quarter size hole?

A rat can squeeze through a like a little hole like that?

They're very smart.

Do you kind of respect them?

No, I kill them.

(all laughing) (bin rattles) Josie's team member, Steve Genaro shows us the low tech tools of his trade.

Let me see this.

So then you cut a slit in the broomstick, You put the spoon in, you wrap it in electrical tape And put a hose clamp on it.

[Steve] Dollar Tree special.

[Josie] Yeah.

You really are saving the taxpayers' money with that contraption there.

[Josie] But it works.

One scoop.

Yeah.

It's two ounces.

And what is this stuff?

It's a bromadiolone, and what it is, the rat is gonna eat this and then they're gonna bleed out.

(dramatic music) [Geoffrey] Ooh.

Oh yes.

And how lethal is that to people?

It isn't, a person, a dog, a cat, humans have to eat half their body weight.

There is an antidote for this.

It's a vitamin K1.

Now, rats are smart.

Do they stockpile vitamin K1 in their burrows?

No, they don't.

They're like, "Hey Marty, get some vitamin K1."

Not that we know of.

We haven't been down there so we don't know.

And they like nest.

Thanks to Steve and Josie, I'm learning that an innocent gap in the pavement might be something more sinister.

Oh yeah, that's a big one.

Yeah.

It's a perfect hole right there, perfect burrow.

[Geoffrey] Wow.

So you hear people say, "Oh I've seen a rat the size of a cat."

Is that an urban myth?

Yes.

(rats squeaking) [Geoffrey] There are no rats the size of a cat.

No, no.

What's the biggest rat you've ever seen?

Yeah, I mean we see big ones.

Yeah, I think people get scared and they just think it was that big.

There's so much to know here.

Do you get creeped out by rats?

I don't, but don't put any ants or a spider in front of me 'cause I'll run, I'll run real fast.

(mellow music) (stapler tapping) [Geoffrey] Do you like doing this?

Yeah.

Yeah?

What do you like about it?

Well, I like doing it, I'm out on the street all day long citywide.

I like baiting.

I like killing the old nest, going back and it being fine and done.

You guys don't look like cold-blooded killers.

(Josie and Steve chuckle) Only eight hours a day.

(all laughing) (bright music) - A visit to the produce section at your local grocery store is like a trip around the world.

Bananas from Guatemala, bell peppers from Canada, dragon fruit from Ecuador, kiwis from New Zealand.

How did this cornucopia get here?

To answer that question, let's visit Chicago's sprawling international produce market - near the Pilsen neighborhood - on the southwest side.

The day starts early here, very early.

Well, it's 2:05 AM, and... It's pretty quiet around here, but not for long.

At Galera Fresh, one of the 22 wholesalers here, orders are already streaming in from grocery stores and restaurants.

And soon enough, workers spring into action, gathering every kind of produce imaginable, and loading trucks for delivery.

Warehouse Manager Kevin Sak spends the wee hours of every work day overseeing the operation.

- Why does it have to be in - the middle of the night?

- Well, because you have - to stock the shelves At the grocery stores before all the customers get in.

- At all hours, trucks back up - to the refrigerated loading - dock, bringing produce From farms all across the country and beyond.

So what do we got here?

- Strawberries.

- Look at that.

Oh man, those look really good.

Oh, yum.

- Somebody who buys that - strawberry box is gonna say, "Wait a minute."

- "There's one missing."

- "There's one missing."

- This one, it's cutting really nice.

Check the sugar now.

- [Geoffrey] Specialized - produce buyers Like Brian Clarke haggle with suppliers, set prices, and make sure the products will keep customers happy.

- [Brian] 11 and 12 is really good.

- [Geoffrey] This little meter.

- [Brian] Yeah, that's a - 13, so that's really sweet.

- Too sweet?

- It could never be too sweet, could it?

- [Geoffrey] Pepe and Paco Vega are twins who own and operate Galera Fresh as third generation produce sellers in Chicago.

- My grandfather started in 1970.

He was one of the first Mexicans, pioneers bringing Mexican produce.

- We had a vision as little kids - when we used to work for my - grandfather and my uncles - That this is where - we were gonna be.

- Chicago has been - a hub for produce Since the late 1800s.

The first wholesale produce market was in the Loop on South Water Street, but the crowded and smelly market became a nuisance as skyscrapers rose downtown.

Elegant Wacker Drive replaced it in the 1920's, and the market moved to 14th and Racine on the lower west side, keeping its name, South Water Market.

When that facility became outdated, the market moved to this state-of-the-art structure near Pilsen in 2001.

Today, the sheer variety of produce here might have stumped the vendors at those earlier markets.

So what is that?

- This is Cherimoya.

- For Hispanic people, they - call it (speaking Spanish), Very popular too, and expensive.

- Dario Uribe and Breck Grigas are specialists in what the industry calls exotics.

What is this?

- This is longan.

- Longan?

- Yeah, those are - coming out of Vietnam.

- Guanabana.

- Guanabana - Yes.

- It looks like something - out of "Harry Potter".

So where is this from?

- [Dario] Mexico.

This is lychee.

- [Geoffrey] I love these.

These are cool.

- What are these?

- [Dario] Passion fruit.

- That's a wonderful aroma.

- Oh, it does!

Smell.

As day breaks, drivers hurry off with their perishable products for a grocery store near you.

- Right, people don't - realize what it takes.

- You go to the store and - you throw a watermelon - In your cart, and you - don't think nothing of it.

You know what I'm saying?

We're up at 2 in the morning to get all this stuff up here.

- What does it mean to you - to be in this business?

- Our life, it's a lifestyle.

- It's our lifestyle.

It's our school, college, university, everything.

We learn everything here.

- A lot of the produce and - other products we bring home From the grocery store come in containers made of plastic and other recyclable materials.

(objects clattering) Now, a lot of us are pretty diligent about recycling, - but if you're like me, - you probably wonder How much of this stuff we put into these blue bins actually gets recycled.

The short answer is we have room for improvement - according to - Sustainability Expert And IIT Professor, Weslynne Ashton.

- Chicago has one of the lowest recycling rates of cities across the country, right?

So we hover around 10%.

- But for the 10% of us who do recycle, the sorting process is amazing.

It happens at a MRF, that's short for Materials Recovery Facility.

This MRF is owned and operated by LRS in Chicago's Back of the Yards neighborhood.

(papers rustling) So if it goes into a blue cart in Chicago, it ends up here?

- Yes, we take in recycling, and we sort it into isolated materials or isolated commodities that we can then market to mills - and factories across - North America.

And so really, we are the sorter instead of the recycler.

It gets recycled in the next phase when we get it to the factory.

- And sorting is a very big job because recycling truck drivers dump their haul in one big pile on the MRF's tipping floor.

To start the process, an electric crane driver scoops up a giant gob of unsorted recycling and drops it on a conveyor belt.

Sustainability Manager Joy Rifkin meets us at the top to start our tour.

It's so noisy here that Joy, who's a former school teacher, uses an old classroom trick, visual aids.

- At this first step, materials - begin to be separated By a rather ingenious spinning spiral thingamajig called an auger screen where heavy materials like glass and metal drop through and lighter materials like paper and cardboard surf over the top.

And that's just the start.

So what's that doing?

- It's separating - two-dimensional From three-dimensional material.

- Steel cans are sorted magnetically.

Most amazing is an optical scanner that identifies material at high speed and then injects puffs of air to send lighter materials up to one sorting area while heavier materials fall down to another.

Somebody's math homework is in there.

Really?

- [Joy] Yeah, looks like geometry.

- Leave it to a former school teacher to spot that.

- For all the computers - and scanners, A lot of this process still requires human power, especially because other humans put stuff in blue bins that doesn't belong there like plastic bags which get caught in the machinery and jam up the works.

I can't even sort my laundry.

I can't get the darks and the lights separate.

- I know, it's hard.

- Sorter Cynthia Torres says plastic bags aren't the only thing she worries about.

(Cynthia speaking Spanish) - A car jack?

No.

Once materials are sifted and sorted, they end up in these massive bales where they await loading into buyer's trucks.

And this is aluminum.

- This is aluminum.

- We also have- - Somebody's White - Claw hard ale there.

- Right, is that yours?

- No, I don't think so.

So how much will actually get recycled?

- On average, 80% of what's - coming into this facility Is getting recycled.

- [Geoffrey] But not all facilities can match that.

- Where the challenge comes is with plastic.

So the recycled plastics compete against virgin plastic that's produced from oil.

- [Geoffrey] When oil prices are low, there's less demand for recyclable plastics, so it can languish in storage, be burned as fuel or even go to a landfill.

- We might not be able to - control the market for plastic, But we can still make better use of those blue bins.

(Cynthia speaking Spanish) (Geoffrey laughs) - I think there's a lot of hope for recycling in Chicago, right?

At 10%, we can only go up.

(cheerful music) - Here at the United Center, - the Bulls have just - beaten the Knicks.

But as one team heads for the locker room, another team takes the floor, literally.

- (playful music) - (ball thuds) Ah!

- Yes!

- (triumphant music) - Okay, I better get - out of the way here Because this crew of 50 doesn't fool around.

- Tonight, we're gonna see it - go from a basketball court - To a hockey rink?

- Yep.

- How long will that take you?

- With the way that we work, two and a half hours max.

- Conversions Chief Dennard Jefferson knows the cold hard facts.

Where's the ice right now?

- The ice, you're - standing on it.

You're right on top of it.

- [Geoffrey] What?

- [Dennard] Yep.

- Apparently, I'm not the only one amazed by that, according to Director of Building Operations, Scott Boyke.

Are people often surprised - that there is ice underneath - the basketball court?

- Always, always, it's a common question, "Is the ice under there?"

It's under there all year long.

(bright energetic music) - They only started this 15 minutes ago, and look at how much is gone already.

- Grab a corner.

- We're just going - to go straight on.

- Oh, that's not too bad.

I just picked up the floor at the United Center.

Like, what was here last night?

- We had a comedy show last night.

- And then tonight?

- We have a Bulls game.

- And tomorrow?

- We have a Hawks game.

- That's exhausting.

- It can be.

- [Geoffrey] But the grind - of constant conversions Doesn't seem to get to Dennard.

- Oh yeah, I'm always hands on.

- Sometimes, I gotta remind - myself that I'm a supervisor.

- I'm just hands on, - I love to work.

- So you love it?

- It doesn't get like routine - after a while, like boring?

- No, when you love what you do, it never gets boring.

- In addition to the floor, - the conversions team removes - several sections of seats And subfloor known as ice decking.

They stow everything in the storage tunnel beneath the stands.

- Okay, it's starting to be - more of a hockey rink now, So I gotta dress properly.

- Boards and glass - replace the seats And workers uncover the ice.

70 minutes in, it's looking a lot like a hockey rink.

- There are rough - edges to smooth out, That's the job of Chicago's Zamboni living legend, Danny Ahearn.

- And you're a former - hockey player?

- Yes.

- What'd you play?

Wait, do that again.

A knee injury ended Danny's hockey career, so he found another way to stay on the ice.

- I worked at an ice rink - and that's how it started.

But I learned how to do the repairs on the refrigeration system.

Actually, I was still in high school.

- [Geoffrey] Danny's biggest pet peeve is spilled drinks - that trickle through - the ice decking - And a lot of it is alcohol, and what does alcohol not do?

It don't freeze.

- With the changeover complete, most of the crew has clocked out, but Danny still has some important business to attend to.

I'm riding the Zamboni.

(cheerful music) Who invented this thing?

- Guy named Frank Zamboni.

- Did you ever meet him?

- Oh yeah.

- Really?

- Oh yeah.

- [Geoffrey] What was he like?

- Normal guy, smart.

(Geoffrey chuckles) - I'll say.

So how many years have you been doing this?

- Between the stadium and here, 43.

- [Geoffrey] 43 years.

- [Danny] Yeah.

- And stop, two hours and 12 minutes, and I'm about to go skating.

(cheerful music) I can't believe I'm doing this.

Before long, this pristine sheet of ice will be hidden again as the crew returns to transform the United Center for the next big event.

(siren wailing) If you've ever had a burning desire to get into show business, Chicago is the place for you.

- [Director] Action!

- (glass shatters) - (flames explode) - (flames explode) - (glass shatters) - [Speaker] Go, go, go, you're all right.

- Cut!

- [Geoffrey] NBC's - top rated series, "Chicago Fire" began filming in 2012 in this massive film studio complex called Cinespace on the city's west side.

And it's the job of these folks to make it look as convincing as possible without hurting anyone.

- This is our burn stage, yes.

- What's a burn stage?

- A burn stage is where we have our fire scenes.

- Steve Chikerotis is a retired fire department deputy district chief and a producer on "Chicago Fire".

What's the scene here today?

- This is a recording studio where we're gonna have a man trapped in this booth.

He'll be trapped here.

- Hey, in here!

I'm dizzy, ah, I'm burning up!

- So this will all be on fire.

- [Geoffrey] This is - all gonna be on fire?

- [Steve] It will.

- [Kelly] Fire - Department, call out!

- [Geoffrey] Well, why - doesn't it just all burn up?

- Because everything you see is made of steel.

This is all steel, all things that won't burn, even the instruments.

- This looks like a piano, but it's just metal.

Oh yeah, look at this.

- These are supposed to be - like a spiral bound book, But it's made of metal so it won't burn.

(knocking on metal) - Crack 12.

- Over the years, we've - gotten quite good At making stuff look reality based, - but actually, when - you put flame to it, - And once you take the flame - away from it, it's not burning.

- [Geoffrey] Before - filming starts, Special Effects wizard John Milinac and his crew set the level of each flame one at a time, so when they're all lit at once, it looks like the room is believably ablaze.

- That's plenty - for now, save that.

- [Geoffrey] Just in case, there are actual firefighters on set at all times.

(flames hissing) (fire extinguisher hissing) Whoops, good thing too.

- Round of applause.

- (crew applauding) - [Geoffrey] So you've - worked in Hollywood?

- Yes, I have.

- What's different about working in Chicago?

- I think the camaraderie of the Chicago crews.

It's really a large expanded family here.

Ready, and one, two, three, fire!

(flames explode) - [Geoffrey] Now, given the - danger, why subject the actors And crew to real fire?

- It has a better feel for it - when we can say we do it live.

Plus, there's some bragging rights to say we do it real.

- [Geoffrey] Interestingly, this giant space was red hot long before it was a film studio.

- Before this campus was Cinespace Studios, it was Ryerson Steel.

There's 1.6 million square feet of space here and it was filled with massive rolls of steel, rolling through these clear span buildings.

- [Geoffrey] The factory - closed after Ryerson was sold In 2007 and was converted to a studio in 2011.

- But there's been a film - industry in Chicago For more than a century.

Selig Polyscope Company on the northwest side cranked out early silent films.

Pioneering Black filmmaker Oscar Micheaux made independent films in Chicago.

Essanay Studios in Uptown is where Charlie Chaplin earned an unheard of $1,250 a week in 1915.

He only completed one film - before heading off - to the west coast In search of milder weather, and the rest of the movie industry soon followed.

- You're the only person I know.

- [Geoffrey] Over the years, - movie making in Chicago Ebbed and flowed with films like "The Blues Brothers", - "Risky Business" - and "Home Alone".

(Kevin screaming) In recent years, Chicago has lured the industry back big time with tax incentives.

As a result, major films and TV series like "Empire", "The Bear", "The Dark Knight", and more have used the city as a backdrop.

(vehicle crashing) - It brings millions - and millions of dollars - To the economy here in Illinois, - in the city of Chicago.

It employs at times thousands of union, trained workers.

It also showcases the city in all its beauty.

- [Geoffrey] And for - retired firefighter And TV producer, Steve Chikerotis, it showcases something else too.

- The tactics that we use on the show are imitations of what the Chicago Fire Department does.

Being able to imitate such a great department as ours, which of course, I believe is the greatest in the world.

(Geoffrey chuckles) I would not trade our team for anybody in the world.

- Whether you're a real firefighter or play one on TV, (wall exploding) - whether you take us places, - (bell dings) Or make those places special, whether your job is glamorous, or gritty or anything in between, you help Chicago live up to its reputation as the city that works.

(bright lighthearted music) (bright lighthearted (music continues) (bright lighthearted (music continues)

Behind the Scenes of "Chicago Fire"

Video has Closed Captions

Clip: Special | 6m 14s | Geoffrey Baer gets a behind-the-scenes look at the set of "Chicago Fire." (6m 14s)

The Chicagoans Reviving Gold-Leaf Sign Painting

Video has Closed Captions

Clip: Special | 3m 28s | Andrew and Kelsey McClellan have revived the delicate, nearly-lost art of gold-leaf sign painting. (3m 28s)

Preview: Special | 1m 11s | Chicago is known as the city that works. Geoffrey Baer explores the city’s unique jobs. (1m 11s)

The Control Center that Keeps Metra on Track

Video has Closed Captions

Clip: Special | 4m 58s | Every day, Metra’s busy control center directs 700 commuter trains across 11 lines. (4m 58s)

Early Mornings at the Chicago International Produce Market

Video has Closed Captions

Clip: Special | 4m 18s | While Chicago sleeps, employees at the International Produce Market start their day. (4m 18s)

Faking Fire on the Set of "Chicago Fire"

Video has Closed Captions

Clip: Special | 4m 55s | How does the crew of “Chicago Fire” make a convincing – but safe – set? (4m 55s)

From Basketball Court to Hockey Rink at the United Center

Video has Closed Captions

Clip: Special | 4m 5s | It takes a quick crew to transform the United Center’s basketball court into a hockey rink. (4m 5s)

Inside a Chicago River Bridge House

Video has Closed Captions

Clip: Special | 4m 31s | It takes a whole team to lift a bridge on the busy Chicago River. (4m 31s)

The Keepers of the Chicago Rat Hole

Video has Closed Captions

Clip: Special | 4m 28s | What happened to the Chicago Rat Hole? One city department sought to preserve it. (4m 28s)

Meet a Rooftop Beekeeper on Chicago’s West Side

Video has Closed Captions

Clip: Special | 5m 52s | Thad Smith runs the Westside Bee Boyz on Chicago’s West Side. (5m 52s)

The Quiet Artistry of the Music Box Theatre's Projectionists

Video has Closed Captions

Clip: Special | 5m 56s | Meet the projectionists keeping movie magic alive at Chicago’s Music Box Theatre. (5m 56s)

Rat Race! Rodent Control in Chicago’s Alleys

Video has Closed Captions

Clip: Special | 3m 50s | Two rodent control workers patrol Chicago’s alleys looking for telltale signs of rats. (3m 50s)

Sorting Recyclables in Back of the Yards

Video has Closed Captions

Clip: Special | 5m 5s | Go inside a recycling facility in Chicago’s Back of the Yards neighborhood. (5m 5s)

The Staggering Logistics of a Suburban UPS Facility

Video has Closed Captions

Clip: Special | 3m 27s | Hodgkins, Illinois is home to the largest UPS ground sorting facility in the country. (3m 27s)

Training Belugas and Salting the Tanks at the Shedd Aquarium

Video has Closed Captions

Clip: Special | 4m 7s | Meet the people who keep the Shedd Aquarium’s animals healthy and the tanks salty. (4m 7s)

What Does It Take to Keep Wrigley Field Running?

Video has Closed Captions

Clip: Special | 5m 6s | Inside the Friendly Confines, a skilled crew keeps Wrigley Field running on game day. (5m 6s)

Wigs, Props, and Other Magic at the Lyric Opera

Video has Closed Captions

Clip: Special | 4m 59s | Meet a wigmaker, prop master, and conductor at the Lyric Opera. (4m 59s)

Providing Support for PBS.org

Learn Moreabout PBS online sponsorshipSupport for PBS provided by:

Chicago Tours with Geoffrey Baer is a local public television program presented by WTTW